Bendpro

Bendpro

Overview

Bendpro delivers high-volume CNC bending, rolling & 3-axis laser cutting with precision. ISO certified, we provide efficient, reliable manufacturing solutions to clients nationwide.

Contact Information

4-6 Industrial Ave

Maryborough West

QLD

Australia - 4650

Phone : + 1800 009 776

Fax :

Mail : [email protected]

Website : https://www.bendpro.com.au

Click Here for More Info!

Contact This ListingGallery

Description

Bendpro delivers precision components with expertise, advanced technology, and a commitment to quality. Our ISO-certified processes in Quality, Safety, and Environmental standards ensure on-time, build-to-print solutions that exceed expectations.

With 40 years of tooling expertise, we streamline design-to-manufacture processes for diverse industries, including Defence. Our lean approach, trusted freight networks, and industry-leading communication ensure seamless project execution nationwide.

Defence Industry Partner

Recognised as the 2019 SME of the Year (Regional) at the Australian Defence Industry Awards, Bendpro strengthens sovereign capability through AIDN membership. We meet Air, Land, and Sea module specifications, supporting OEM, MRO, and Defence sustainment projects.

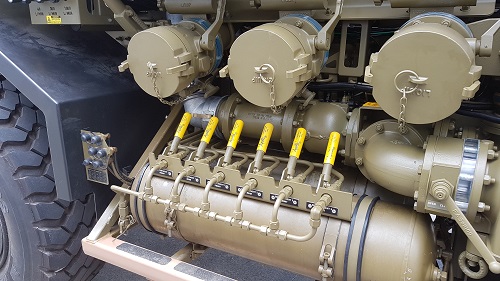

Our precision manufacturing ensures accuracy for military vehicles, naval equipment, and maintenance tools. With world-leading technology, fully traceable workshop practices, and a focus on safety and environmental sustainability, we set the standard for Defence manufacturing.

Bending, rolling, hydraulics and fabrication

Bendpro’s advanced CNC mandrel bending and rolling machinery enables precise, repeatable manufacturing at scale. Skilled in fluid transfer and hydraulic feedline packages, we deliver solutions from feasibility to final production—ensuring reliability at every stage.

Discriminators

• ISO certified – Quality, Safety, Environment.

• Nationwide Service.

• Largest tooling range for CNC Mandrel Bending in Australia.

• 6 x CNC mandrel bending machines.

• 95% DIFOT (Delivered in Full on Time).

• 3D Laser Scanning – Romer Arm.

• Dedicated Customer Care Team for Superior Support.

• 3-Axis Tube/Angle Laser Cutting Machine.

• End-to-End Support: Design, Prototyping & Production.

Capabilities

• Materials: carbon steels, stainless teel, alloy steel, aluminium, brass & copper.

• CNC tube and pipe bending (ø3.18mm diameter tube to 100NB pipe).

• CNC SHS Bending (12.7mm SHS tube to 75x50 RHS).

• CNC tube and pipe rolling (ø12.7 tube to 40NB pipe/50.8 tube).

• Section Rolling and Bending to 80NB/75SHS (e.g. RHS, SHS, Flat Bar, Angle).

• Prototyping and product development.

• CAD & SolidWorks Capabilities3D Laser Scanning (Romer Arm) & Reverse Engineering.

• Swaging, Notching & Scalloping.

In-House Fabrication

• Drilling

• Punching

• Trimming

• Pressing

• Grinding

• Machining

Hydraulic End Forming

• JIC, O-Ring, Bulge, Bead, Victaulic Groove

• Hydraulic pressure testing

• Polishing

Welding

• MIG, TIG, brazing (WPS-qualified procedures available)

• Assembly & FIS service

• 3-Axis laser cutting

Awards

• 2023 QLD Training Awards North Coast Regional Finalist.

• 2022 Fraser Coast Tourism & Business Awards Winner.

• 2022 Business & Tourism Awards Chamber President’s Award Winner.

• 2022 Business & Tourism Awards Trade and Manufacturing Winner.

Key Personnel

National Business Development Manager: Clayton Rowland

General Manager: Allen Ascough

Quality Assurance

• Quality – ISO 9001:2015

• Safety – ISO 45001:2015

• Environment – ISO 14001:2015

Head Office

PO Box 1108

Marborough QLD 4650