Dabico Airport Solutions

Dabico Airport Solutions

Overview

Dabico Airport Solutions (formerly Cavotec Airports) is a leading ground support equipment manufacturer with a comprehensive range of products and services for commercial and defence applications.

Contact Information

Room 11, 6th Floor, Kowloon Plaza

No. 485 Castle Peak Rd

Cheung Sha Wan

Hong Kong

Phone : + 852 2791 6161

Fax :

Mail : [email protected]

Website : https://www.dabico.com

Contact This ListingGallery

Description

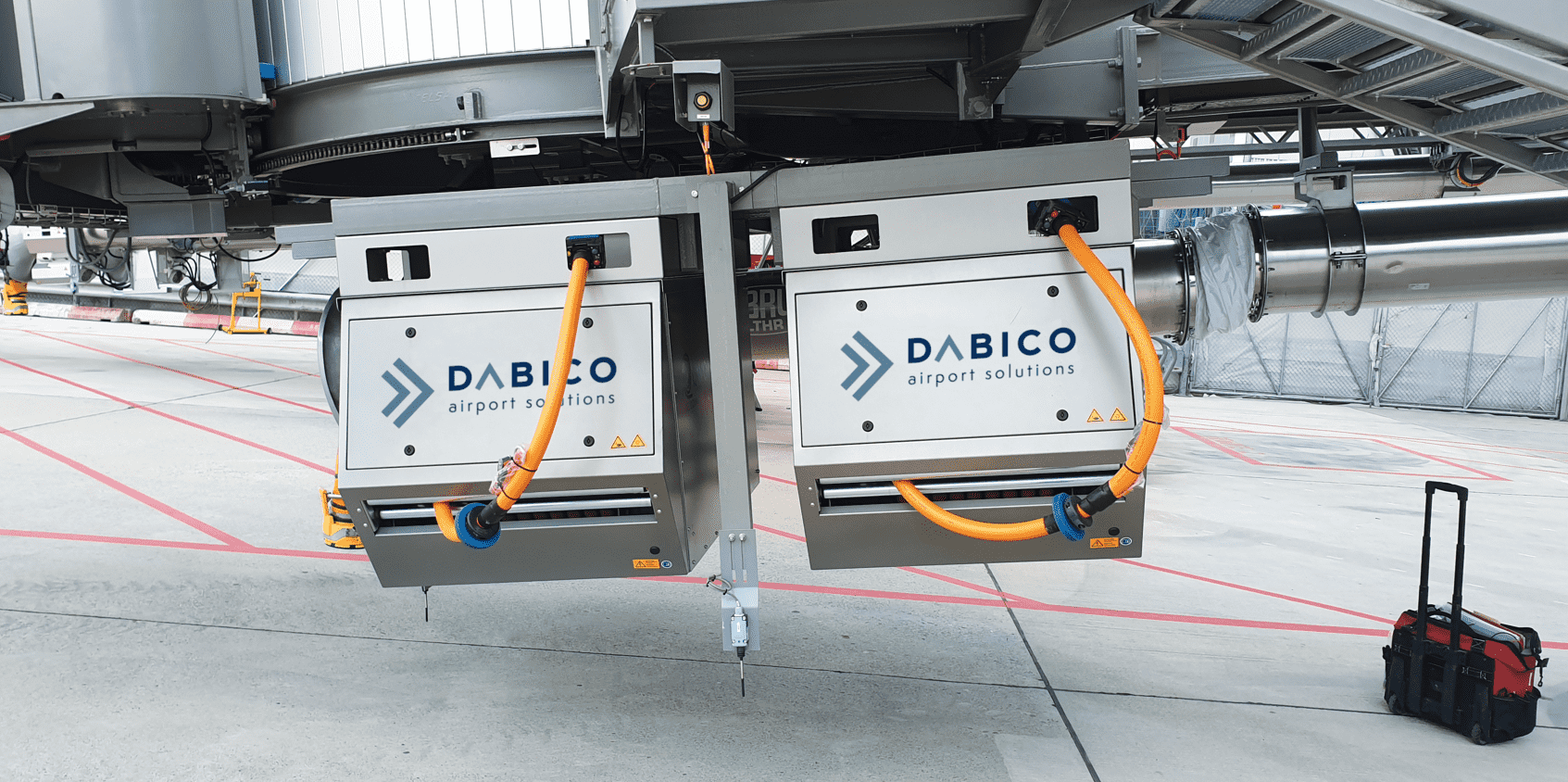

DABICO Airport Solutions designs, manufactures, and integrates ground support systems for use in both the civil and the military aviation sectors.

With more than 50 years of experience in the industry, we are one of today’s leading clean-technology companies, providing and maintaining innovative connection and electrification equipment that helps to decarbonise airports, and to make them safer, and more sustainable and efficient.

DABICO has facilities in three countries around the world, and employs over 200 skilled personnel who represent a large number of cultures, and who provide our customers with local support that is backed by the global reach of the Group’s engineering expertise.

Dabico’s defence experience comes from developing and supplying critical equipment for defence forces around the globe as per strict specifications and for specialized applications.

DABICO contributes to a future world that is cleaner, safer and more efficient by providing innovative connection solutions for Airport, aircraft and mobile equipment today.

We provide Power, Air, Fuel and water to parked Aircraft. DABICO with 50 plus years’ of experience as OEM, we provides complete turnkey solution, engineering service / support for various Airports worldwide. DABICO’s cutting-edge products and solutions provides alternate system to APU and reduces tarmac congestion, improve overall performance, safety and efficiency, reduces the environmental impact and increases the profit to the customers.

DABICO is a turnkey system contractor for APRON Equipment for Aircraft. DABICO has developed itself with new areas of expertise such as in the airports, where the company offers Design, System Integration, and Project Management services for its clients willing to modernize their airport facility by implementing state of the art design and technologies. We develop technologies for our own customers, and as a trusted partner of leading OEM.

Our innovative solutions include integrated 400Hz, 270VDC and 28VDC Ground Power Units (GPU), 400Hz eGPU, Aircraft Power Connectors and Cables, Caddies, Cable Crocodiles, Tow Bars, Motorised Cable and Hose Coilers including the innovating Jet Cable Friend, Pre-Conditioned Air (PCA) systems, Fuel systems, Aircraft Ground Connection (AGC) systems including in ground hatch and pop-up pits for Hardstands and MRO Hangar applications.

Fuelling

DABICO's engineering and systems integration expertise has seen the Group lead the development of aviation ground fuelling solutions for military and civil applications for many years.

DABICO has been at the forefront of providing aviation fuel hydrant system solutions since the first fuel hydrant systems were developed in the early 1960's. DABICO fuel hydrant pit solutions enable refuelling via an underground fuel hydrant pipeline. All major airports have adopted the fuel hydrant system, reducing airport congestion, and improving safety.

DABICO E3 Fuelling illustrates our wide fuelling portfolio engineered and manufactured based on the highest industry standards (API, TüV, STS-M, EI, UFC, UFGS).

Dabico Pits are installed in commercial and military airports throughout Australia and New Zealand. These pits are designed for use with Fuel Hydrant, Water Hydrant, and Fire Hydrants Systems. Applications of these pits include Fuel Hydrants Pits, High Point and Low Point Pits, Isolation Valve Pits, Cathodic Protection Pits, Water and Fire Hydrants Pits, as well as Electrical Pits.

Dabico's engineering and systems integration expertise has seen the Group lead the development of aviation ground fuelling solutions for military and civil applications for many years.

Dabico has been at the forefront of providing aviation fuel hydrant system solutions since the first fuel hydrant systems were developed in the early 1960's. Dabico fuel hydrant pit solutions enable refuelling via an underground fuel hydrant pipeline. All major airports have adopted the fuel hydrant system, reducing airport congestion, and improving safety.

Dabico E3 Fuelling illustrates our wide fuelling portfolio engineered and manufactured based on the highest industry standards (API, TüV, STS-M, EI, UFC, UFGS).

Dabico Fuel systems include

- Fuel Hydrant Pit Boxes

- High Point and Low Point Pit Boxes

- Fuel Hydrant Valves, Under Hydrant Valves, High Point and Low Point Assemblies

- Prefabricated Isolation Valve Chambers

- Easy opening Vault Access Covers (various sizes)

- Cathodic Protection System Test Stations

- Hose free military direct refuelling arms (pantographs)

Dabico is the market leader for hose free military direct refuelling arms (pantographs) used by military throughout the globe.

Dabico Pit Boxes can be supplied with either waterproof Tethered, or 180 degree “Lay Flat” Hinged Lids, all with a 90T Load rating.

Our fuel hydrant pits are in compliance with all necessary JIG standards, including JIG Bulletin 90. Dabico’s comprehensive range of systems meet all aircraft requirements including the New Aircraft Generation (NGA) such as the A380, B787 and A350, and military aircraft such as KC-30A, C130J, P-8A Poseidon, E-7A Wedgetail, MH60R. MRH90, F/A-18A Super Hornet, and F-35 Lightning II Fighter Aircraft.

400Hz Power

Dabico Aircraft Power Connectors and Cables are in use throughout Australia and New Zealand, in MRO Hangars, Aircraft Aprons, and on Navy ships, as well as Motorised Power Cable Reelers, Ground Power Units (GPU), Pre-Conditioned Air (PCA) systems, including the in-ground fuel systems along with above ground direct fuelling pantographs.

Dabico offers an extensive range of systems and services for commercial and military MRO hangars. Our advanced GSE systems help modern facilities to provide a complete spectrum of maintenance and overhaul services for fixed- and rotary-wing aircraft.

We also support a wide variety of customers with the design and engineering of maintenance base layouts, including 400Hz ground power, PCA, Utility Pits and fuel exhaust systems.

Dabico holds one of the world’s largest customer base of commercial and military MRO facilities and assembly lines. Our systems are used in Airbus A350, A380 and Boeing 787 hangars and assembly lines, at Lockheed Martin and Airbus Helicopter assembly lines, and by air forces and naval bases.

400Hz-eGPU

The new Dabico 400Hz-eGPU charges faster, has higher power rate, a longer battery life and work smarter.

Dabico 400Hz-eGPU is a Battery powered 400Hz Converter 1x90kVA to support Aircrafts with electrical energy for Gate stands, Remote stands and Hangars. We recommend the Dabico 400Hz-eGPU as a permanent 400Hz converter solution or as temporary replacement for a stalled 400Hz fixed installation.

Benefits of the Dabico 400Hz-eGPU:

- Last LONGER, (up to 11 hours of operation resulting in 14 turnarounds)

- Re-charge FASTER, (from 1,30 hours)

- Work SMARTER

- Connected (Wifi, 5G, integration in Customer network and monitoring system)

- Designed for easy Operation and Maintenance.

- Charging Hub

- Regular Maintenance contract optional

- Leasing services

- Operating temperature range of -30 to +56°C

- Greater overall efficiency from mains to aircraft

- No break power transfer functionality

Dabico 400Hz-eGPU is not only beneficial operationally, it is also a greener solution. It provides several health, quality of life and environmental benefits for your employees such as:

- CO2 + NOX emissions free

- Virtually noise-free

- Human health

- Less costs more revenue

- Charging and discharging

- Ease of operation

- Ease of service

Powering Aircraft

With the Dabico 400Hz Ground Power Units Series 2500+, we offer to the industry the ultimate 400Hz solid state frequency converter integrating the highest electrical and communication performance having the following characteristics:

- ISO 6858 Certification

- Up to 500% Overload

- 90kW Unity Power Factor supporting the new generation aircraft

- 94% efficiency ensures a reduced electricity consumption

- Low Input and output THD for a clean and stable power grid

- Robust design for ensuring a high serviceability and ROI

- Dual output capabilities

- Ground Power Units (GPU) meeting the requirements of all military aircraft, both point of use and centralised (motor generator) systems. Point of use systems can be ground mounted, bridge mounted, or mobile GPU. Dabico’s Powerpack I-Connect model is a combination of GPU and motorised cable coiler. Weatherproof covers used by military are also available.

- Aircraft Jet Cable Assemblies

- 400 Hz Connectors - XP Series (28XPV NSN: 5935-12-380-3838, 400XPV NSN: 5935-12-380-3822/ 3836/ 3838 / 1838, 400XPV-S NSN:5935-12-380-4155) and SP Series

- 400Hz Aircraft Power Cable – 3 x 50, 3 x 70, 4 x 50, 4 x 70, and 7 x 35

- 400Hz Cable Coilers, Caddies and Crocodile Systems. Cable Coilers can be gantry mounted, on ground stand, or installed within a pit.

Aircraft Ground Connection (AGC) systems include in-ground hatch and pop-up pits for Hardstands and MRO Hangar applications, allowing easy access to all service outlets, making servicing safe and efficient with the actual service points rising above the hangar floor.

Our systems distribute 400Hz power, Pre-conditioned Air (PCA), potable and blue water, fuel and remove sewage. Connected to Dabico 400Hz GPU or PCA, they ensure a safe, efficient and reliable powering and cooling of aircraft on the ground. Dabico provides customised solutions for Fuel Exhaust / Tank Ventilation, Mass Flow Air, Utilities - 50Hz Power, RJ45 data, Compressed Air, and Water. Also Pedestal and Cable Rack systems are available.

Dabico in-ground pits include hatch covers and pop ups for concrete chambers or fully self-contained steel or fibreglass chambers eliminating most of the concrete work and assures quick installation on site. Our pits can be manufactured to operate in IEC Ex Zone.

Pop-up and hatch pits are rated Load Class EN 124 F900, withstanding the toughest working environments and are suitable for in and outdoor operation, hangar or remote parking. As environmentally friendly solutions, they help contribute to the CO2 reduction program at today’s modern airports.

In-ground pits have been recognised as the most efficient and safe way to service aircraft on the ground and prevent damages to aircraft due to potential mobile Ground Service Equipment collision with the aircraft.

Pre-Conditioned Air Systems (PCA)

Dabico Pre-Conditioned Air Systems (PCA) are in use to cool large military aircraft and fighter jet aircraft.

DABICO has led the development of aircraft ground cooling systems for five decades. DABICO is the only supplier of fully integrated PCA systems and the broadest offering with either Point of Use (DX PCA) or Central system (AHU or DX-Hybrid) and in full compliance with IATA AHM974 and AHM997. All electrical, fixed or mobile, Dabico PCA improve the airport environmental footprint.

DABICO PCAir system was the world’s first approved AHM997 installation in 2009 at Bahrain International Airport.

Our 8,500 PCA worldwide installed base ensures aircraft APUs up to the Airbus A380 can be switched off under the harshest ambient conditions such as in the Middle East or South East Asia. We design and engineer our PCA systems based on the most challenging industry standards including the ASHRAE and AHM.

We optimise the entire system design including power requirement and air distribution flow and temperature from the PCA outlet up to the aircraft PCA inlets. Our engineering guarantees that we meet each single aircraft cooling requirement. DABICO unrivalled PCA in-ground pits systems boost the overall system performance and ensure a better passenger comfort on-board the aircraft.

Dabico has an installed base of 2400+ PCA worldwide installations engineered in compliance with AHM974 (Conventional PCA) and AHM997 (Sub-freezing PCA).

- Mobile electric DX PCA DX Series - Electrically powered with Vapour cycle Direct Expansion

- Point of Use DX Series PCA - Electrically powered with Vapour Cycle Direct Expansion

- Central PAC (AHU) PAC Series - Air Handling Unit with 1 or 2 water circuits (EGW or CW+EGW)

- Central DX-Hybrid PCA Arctic Series - 2 cooling stages - Chilled Water + Vapour cycle Direct Expansion

- Central DX-Hybrid PCA Sub-Z (CW + DX) Arctic Series – 3-4 cooling stages - Chilled Water + Vapour cycle Direct Expansion

- Central PCAir Series - Brayton cycle – Expanded Pre-compressed Air

The air from the PCA system can be distributed to the aircraft by conventional flat hose reels or underground insulated ducting to either a pop up or hatch PCA Pit, which offer a convenient way to access and store either flat or spiral PCA hose for connection to the aircraft.

Air Distribution options are

- PCA Hose Basket - Flat hose stored in a basket (Bridge Mounted)

- PCA Manual Hose Reel - Flat hose reeled on a small carriage (Apron Mounted)

- PCA Hose Retriever - Motorised hose reel (Bridge Mounted)

- PCA Hose scissor (Ground Mounted)

- PCA Hatch - Hatch pit with 1 or 2 reinforced hard-drawn PCA hose(s)

- PCA Pop Up - Pop-up pit with 1 or 2 steel spiral reinforced PCA hose(s)

Wet services

DABICO’s Wet Services have revolutionized the airport industry. Engineered in partnership with Aqseptence Group and Roediger Vacuum GmbH, DABICO system ensures wet services are provided through in-ground pits and eliminates the need of mobile GSE.

They present an innovative and modern servicing solution which has proved to be both economic and efficient in challenging sewerage projects throughout the world.

As a system specialist, DABICO offers turnkey solutions with a design based on two primary parts: a central treatment plant, (including potable / blue water generation and storage, and a sewage vacuum system); which is connected to in-ground pit systems located at the aircraft stand.

Our Technology

A central treatment plant where potable and blue water is generated and stored before distribution while vacuum pumps and tanks will extract the wastewater from the aircraft.

Sewage is discharged from the aircraft by vacuum and subsequently either collected in storage tanks or discharged directly in the airport or municipality network.

Potable and blue water is distributed to each aircraft parking position through underground pipes from the central wet services plant.

In-ground pits will be connected to the aircraft by the ground-handling team via flexible hoses stored into the pit. Aircraft industry has standardized the connectors which ensure a standard system approach.

Utility Services

IN-GROUND UTILITY PIT SYSTEMS

DABICO designs and manufactures pop-up and hatch pit systems that service aircraft at contact gates, remote parking areas and in MRO hangars. Our systems distribute 400Hz power, Pre-conditioned Air (PCA), potable and blue water, fuel and remove sewage.

Connected to DABICO 400Hz GPU or PCA, they ensure a safe, efficient and reliable powering and cooling of aircraft on the ground.

DABICO in-ground systems are either used in combination with our tunnel system, or placed in individual concrete chambers, which can be delivered precast or be cast on-site. An optional steel or fiberglass chamber eliminates most of the concrete work and assures quick installation. DABICO in-ground systems are equally suited for use in hangars.

All DABICO in-ground pit systems have an aircraft loading rate capacity based on Load Class EN 124 F900 and withstand the toughest working conditions. As environmentally friendly solutions, they help contribute to the CO2 reduction program at today’s modern airports.

POP-UP AND HATCH PITS

DABICO Fladung’s Pop-up and hatch pits allow easy access to all service outlets, making servicing safe and efficient with the actual service points rising above apron level.

Pop-up and Hatch pits are rated Load Class EN 124 F900 and withstand the toughest working environments and are suitable for in and out door operation, hangar or remote parking. In-ground utility pits are being used for delivering 400Hz power, PCA, potable and blue water and removing sewage from the aircraft. All those services can be operated by one single ground handling operator. For an A380 position, only 4 pits will be required for providing those five services.

In-ground pits have been recognised as the most efficient and safe way to service aircraft on the ground and prevent damages to aircraft due to potential mobile Ground Service Equipment collision with the aircraft.

TUNNEL SYSTEMS WITH IN-GROUND UTILITY PITS

When using a full-scale tunnel system with hatch or Pop-up pit systems from DABICO, all essential ground support services are available close to parked aircraft. This improves not only operational efficiency, but also reduces environmental impact.

With the introduction of double-deck, wide-body aircraft such as the Airbus A380, existing supply systems are no longer sufficient, creating even more challenges in terms of space, costs and efficiency. Our tunnel system offers a long-term solution to these challenges, because it allows the inclusion of additional services in the future.

Design services

DABICO Airport Design Services (CADS) specialises in Airport Electrical & Mechanical Design Services.

We design advanced, specialised systems for airports and MRO hangars including 400Hz, PCA, wet services, fuel hydrant and tank farm systems.

DABICO high quality consulting services focus on in-ground and above ground GSE systems leading the way of modern airport ground handling operations and playing a fundamental role in bringing lower operational expenses, higher ramp safety levels and reduce carbon footprint.

We provide expert advice, making use of our extensive knowledge and experience, for contact gates, remote aprons and hangars to suit all types of operations and aircraft.

This specialised division in the company has been developed based on strong market expectation to award experts in the field of airport systems, capable of designing turnkey solutions and integrating systems which require complex interfacing and coordination.

DABiConnect

DABICO’s integraed airports solution - DABiConnect - reduces operational costs and increases efficiency and revenues.

Our integrated airports solution, DABICO DABiConnect, connects all GSE assets including GPU, PCA, Visual Docking Guidance Systems (VDGS), passenger boarding bridges, potable water systems, sewage and blue water systems, in-ground pit systems and other aircraft stand equipment.

DABiConnect is a cloud-based solution with enhanced cybersecurity that integrates with airport operator databases (AODB) and airport billing systems to enable automated billing for airlines. The technology monitors and records all operational parameters and actions of gate equipment for all aircraft. It is an innovative and powerful remote operations management solution that enables users to monitor real-time data and operational status remotely.

DABiConnect provides:

- Geo-location, live operational parameters, fault warnings, diagnostics, real-time alarms or notifications

- Storage of operational and maintenance history, service history management, breakdown service and AMC including online monitoring

- Pre-alerts in line with OEMs’ recommended preventive/predictive maintenance schedules

- Estimated costs, manpower and duration requirements on daily and weekly maintenance

- Option to integrate with spare parts ordering based on O&M spare parts manual through existing ERP solution

DABiConnect is expandable to accommodate additional aircraft stands or equipment. Fully integrated and automated solutions including automatic billing for airlines, resulting in accurate billing and greater efficiency.

Our Predictive Analytics Solution (PAS) package provides notifications and equipment diagnostics, reducing downtime, improving reliability and reducing operational and maintenance costs.

DABICO has developed DABiConnect based on experience and data collected over four decades from airports worldwide.

DABiConnect enables:

- Predictive maintenance, spare parts and resource management optimization

- Maintenance based on actual equipment use

- Improved reliability, reduced downtime

- Continuous monitoring and analysis of equipment performance using real-time and historical data

- Failure analytics to automatically identify previous events and provide solutions to significantly reduce Mean Time To Repair

- Minimum level of inventory and direct integration with ERP

- Improved training of technicians and operators based on historical data and advanced diagnostics systems

- Asset management and KPI-based personalized dashboards for different user groups

- Smartphone and tablet operation

- Integration with third-party equipment

- Integration of multiple airports under one group

Service for Airports

Service is a critical component of DABICO’s approach to its customers. Our local sales offices, located around the world, are backed by the expertise from our research and engineering centres and are ready to respond to any service and support request.

DABICO offers various levels of service and support for installation and maintenance of ground support equipment. Our service teams are also on hand for any repair projects that might need to be undertaken, either on or off site.

We also provide on-site commissioning and training, as well as dedicated training classes at our own Centres of Excellence. Using in-depth manuals and system documentation our fully qualified staff can provide all levels of training and maintenance instruction, in-line with your operational requirements.

Our sales offices around the world offer our customers local expertise backed by our global network of Centres of Excellence engineering.

Key Personnel

Regional Sales Director (Asia Pacific): Raymond Wong

Chief Commercial Officer: Alex Pfurr

Chief Executive Officer: Juergen Strommer

Quality Assurance

ISO9001:2015 Quality Management System,

ISO14001:2015 Environmental Management System,

BS OHSAS 18001:2007 & AS/NZS 4801:2001 Health and Safety Management System

Regional Offices

Dabico Dubai Dabico FZE

Jebel Ali Free Zone, South,

P.O.Box 61124

Dubai, United Arab Emirates

Dabico UK

Dabico Airport Solutions UK Ltd

32 Jay Avenue, Teesside Ind. Est.

Stockton-On-Tees TS17 9LZ United Kingdom

Dabico Germany

Dabico Airport Solutions Germany GmbH

Gottlieb-Daimler-Straße 7

63128 Dietzenbach, Germany

Dabico US

Dabico Airport Solutions, Inc.

5665 Corporate Ave

Cypress, CA 90630 USA

Dabico Hong Kong

Dabico Airport Solutions Hong Kong Limited

Room 11, 6th Floor, Kowloon Plaza

No. 485 Castle Peak Road, Cheung Sha Wan

Hong Kong